STAMPED CONCRETE OTTAWA

Hire us for your stamped concrete project because we have the expertise to make sure your project is completed correctly and will stand the test of time.

• Driveways

• Patios

• Walkways

• Pool Surrounds

• Steps

Request a Quote!

Feel free to provide detailed information about your project so that we can respond with a ballpark price.

What is Stamped Concrete?

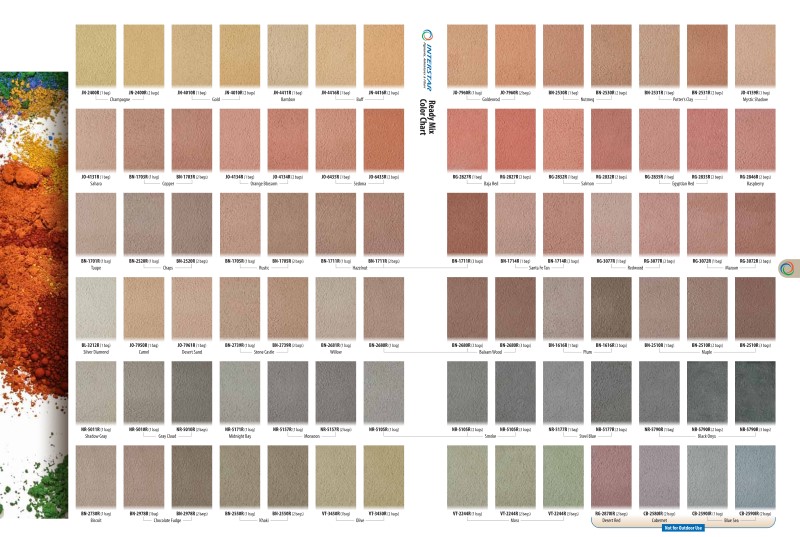

Stamped concrete is concrete that has been textured, patterned or imprinted to resemble brick, interlock, slate, flagstone, stone, or even wood. This stamped look is created by placing heavy stamps into concrete while it is still wet. Stamped concrete is often coloured and with an integral colour added to the concrete mix and a secondary colour added after pouring that helps highlight the textures and patterns. The wide variety of patterns and colour choices make it popular for beautifying patios, pool decks, driveways, walkways and more. Additionally, it is often more affordable, longer lasting, and requires less maintenance than other materials

Stamp Patterns

Monterray Ashlar

Random Stone

Blue Stone

Classic Wood

Our Stamped Concrete Process

Excavation & Base Prep

The first step in creating a beautiful concrete slab is to build the base. In Ottawa we have a major freeze thaw cycle due to the drastic temperature changes of our climate. Therefore it is important to dig deep and properly compact the base material. We dig down 12" and lay landscape fabric at the bottom of the excavated area to separate the soil from the granular "A" stone base material. We then add about 8" of granular "A" crushed stone compacting every 2.5" or so. This ensures a solid base that will not shift during freeze thaw cycles and helps prevent cracking.

Forming

After the base is in place we set the forms. The forms are set to conform with the design plan and to ensure proper water drainage. Our forms are built from wood and nailed to either steel or wooden stakes. We coat the forms with oil before pouring so that they come apart from the concrete easily. Just before the pour we double check our form placement and make any required adjustments.

Pouring & Finishing

Concrete is delivered to the work site. If we are using coloured concrete the dye will be mixed in at the concrete plant. The concrete is poured inside the forms, raked and screeded out to grade. Next we bring the concrete to a smooth finish to prepare for stamping.

Stamping

With the surface and edges brought to a smooth finish we then wait for the concrete to reach the right level of firmness before stamping. The first step in stamping is to broadcast release powder evenly over the slab. Concrete powder release agent forms a moisture barrier between the stamps and wet concrete to allow the stamps to release easily from the concrete. In addition to releasing agents the powder adds colour variations and highlights to the textured surface.

We use the touch up wheel to fix joints where concrete got squished up between stamps. We also do detail work agaisnt the walls where stamps can't fit.

Cutting & Cleaning

After stamping we wait 24 - 36 hours and then sweep off excess release powder with a soft broom. More release powder is cleaned off with water, dish soap and a soft brush. We also do the crack control cuts at this time so that the concrete cracks in these precut lines and doesn't create unsightly cracks in your new surface. About one week after pouring we will do a final wash with acid to remove excess realease powder and prepare the surface for sealing.

Sealing

With the surface washed and cut and after waiting one week or so for the concrete to cure we finally apply a coat of sealant. Concrete sealant helps prevent damage, corrosion and staining caused by oil, chemicals, salt, grease, weather exposure, UV rays, and moisture. Sealing also accentuates the colours and textures in the stamped surface. About one month after pouring we will often add another coat of concrete sealant.

How We Build: Stamped Concrete Driveways

If you are considering building a new driveway or replacing an existing one in Ottawa you are likely weighing the options between asphalt, interlock or concrete. Since concrete driveways are more expensive to install than asphalt and also more expensive to remove you will want to be sure that yours is constructed correctly in order for the investment to make sense. Below we explain some things that you may want to keep in mind while planning the construction of a concrete driveway.

Excavation & Base

Everyone living in Ottawa knows that we experience vast temperature differences between peak summer heat and the depths of winter cold. This causes the ground to freeze deeply and then thaw completely resulting in movement and shifting of any ground that retains a lot of water. Therefore soil and clay need to be dug out and replaced with crushed stone.

Our recommendation for a driveway base is the following:

- Excavate 2 feet deep.

- Over-dig by at least 1 foot on either side of driveway.

- Add geo-cloth landscape fabric and geo-grid.

- Add 4 inches deep of Granular B (dust to 4" diameter) stone.

- Add 14 inches deep of Granular A (dust to 3/4" diameter) stone.

- Compact the base every 4 inches using a diesel plate compactor or vibrating roller.

Reinforcement

We reccomend rebar with at most 2 foot spacing plus welded wire mesh for driveway reinforcement. This may seem like overkill but in our opinion it is better to have too much reinforcement than too little.

Concrete

We pour driveways at a minimum of 6" thick. We use concrete with a 28 day compressive strength of 30 MPa, with 8% entrained air and fibre mesh.

Watch:

How We Build: Stamped Concrete Walkways & Patios

If you are considering building a new walkway or patio in Ottawa you may be weighing the pros and cons of interlock and concrete. Below we explain the way we go about constructing concrete walkways and patios so that you can make an informed decision.

Excavation & Base

Everyone living in Ottawa knows that we experience vast temperature differences between peak summer heat and the depths of winter cold. This causes the ground to freeze deeply and then thaw completely resulting in movement and shifting of any ground that retains a lot of water. Therefore soil and clay need to be dug out and replaced with crushed stone.

Our process for building for a walkway or patio base is the following:

- Excavate 12"-18" deep.

- Over-dig by at least 6" around perimeter.

- Add geo-cloth landscape fabric.

- Add 8"-14" deep of Granular A (dust to 3/4" diameter) stone.

- Compact the base every 4 inches using a plate compactor.

Reinforcement

We use welded wire mesh for walkway and patio reinforcement.

Concrete

We pour walkways and patios at a minimum of 4" thick. We use concrete with a 28 day compressive strength of 30 MPa, with 8% entrained air and fibre mesh.

Frequently Asked Questions

How long will stamped concrete last?

Stamped concrete will last for decades when properly installed and maintained, even in Ottawa's climate where it will be exposed to harsh winter weather conditions and freeze thaw cycles. We at McExcavate also seal our stamped concrete projects to protect the surface from abrasion and wear and make it easier to maintain.

What kind of maintenance is required?

Cleaning and resealing of the stamped concrete surface should be done every 2 to 3 years or so, but depends on the use the area is subjected to, foot or car traffic, weather, chemicals, etc. Before resealing just simply clean the surface with a garden hose or pressure washer along with some mild soap and a push broom. While concrete sealant makes the surface stronger, more resistant to abrasion, and helps block the penetration of water, stains, dirt and chemicals it is still a good idea to remove grease, oil and other spills right away.

Does stamped concrete look fake?

Stamped concrete looks very realistic because most stamping mats are molded from the actual materials they are designed to replicate. To achieve natural-looking colour variations as found in real stone or wood, we use an integral colour in the concrete mix along with an accent colour added to the surface of the concrete using stamping release powder.

Is stamped concrete slippery?

Due to it's textured surface stamped concrete is often more slip resistant than broom finish concrete. However, just like natural stone, it can become slippery when wet. If it will be installed in a high-traffic area stamped concrete's slip resistance can be improved by using a heavier texture or adding a skid-resistant additive to the sealer.

Does stamped concrete crack?

Stamped concrete is resistant to cracking when installed correctly. However since some cracking is likely to occur we cut crack control joints into the concrete where we predict cracking is likely to happen. If stamped concrete experiences minor cracking, the cracks are often hard to detect because they will often blend in with the pattern and joint lines.

Related Blog Posts

5 Ideas for Concrete Pool Decking

Feb. 17, 2025, 9:12 p.m.

Author: conormc

When it comes to designing the perfect pool area, the right decking can make all the difference. Concrete is a popular choice for pool decks due to its durability, versatility, and cost-effectiveness. But plain concrete...

What Are the Best Pool Decking Options?

Feb. 13, 2025, 6:10 p.m.

Author: conormc

Choosing the right pool decking material involves considering durability, maintenance, safety, heat retention, and design. Below, we compare four popular options: Concrete, Interlock (Pavers), Wood, and Composite ...

6 Types of Concrete Finishes

Feb. 11, 2025, 9:33 p.m.

Author: conormc

Welcome to our guide on concrete finishes! Concrete can be more than utilitarian; it can be stunning. Here, we'll explore six types: smooth, broom, spin trowel, stamped, exposed aggregate, and grinding and polishing. Each offers unique benefit...

Can You Stamp Concrete Over Existing Concrete?

Jan. 20, 2025, 6:59 p.m.

Author: conormc

Existing concrete can have a stamped layer added over top of it. Often, older concrete slabs will become worn out and chipped or cracked but remain structurally sound. These cracks and chips can be repaired and then a layer of stamped concrete can...

Concrete Crack Control Joints - Tooled vs. Sawed

Jan. 20, 2025, 2:33 a.m.

Author: conormc

What are crack control joints?

Outdoor concrete will always crack. Even thick concrete that is installed correctly. Therefore grooves called control joints m...

How Much Does Stamped Concrete Cost In Ontario?

Dec. 5, 2023, 9:46 p.m.

Author: conormc

There are many factors that affect the cost per square foot of your stamped concrete project. The most important factor is the complexity of the stamping and colouring. Other factors that will affect the price are; the ...

What are the disadvantages of stamped concrete?

Oct. 28, 2023, 2:50 p.m.

Author: conormc

If you're considering putting in stamped concrete on your property it is likely that you're also considering some other surfaces like interlock, broom finish concrete, asphalt or many others depending on the application. While stamped conc...

Is Concrete Damaged by Ice Melting Salt?

Nov. 18, 2022, 2:34 p.m.

Author: conormc

Salt itself does not chemically react with concrete and cause damage. The damage is caused when ice melting salt lowers the freezing temperature of snow and ice turning it into water, the water enters the pores and cracks of the concrete, freezes ...