What are crack control joints?

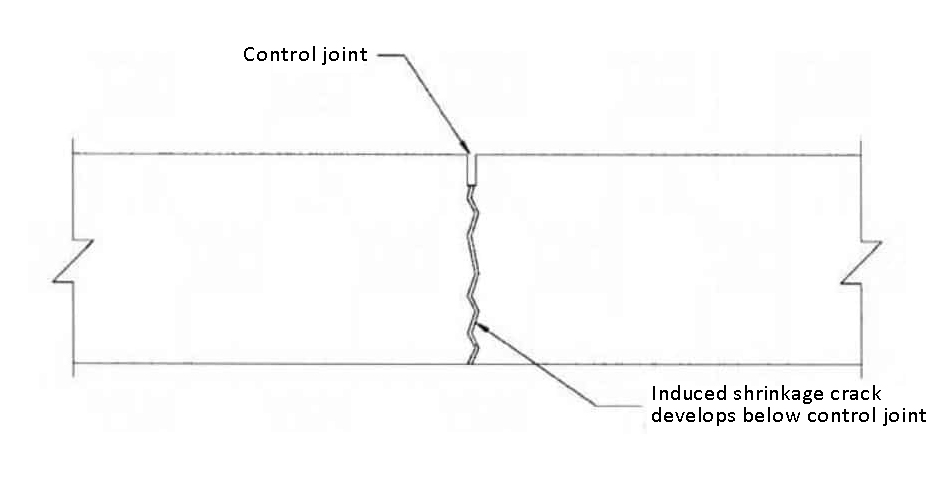

Outdoor concrete will always crack. Even thick concrete that is installed correctly. Therefore grooves called control joints must be cut or tooled into the concrete where it is expected to crack. These joints encourage the concrete to crack along those lines making the cracks invisible. There are two types of control joints; tooled and saw cut.

Saw cut joints:

Saw cut joints are cut into the concrete using a concrete saw after the concrete has hardened. They should be about ¼ the thickness of the concrete slab.

Pros:

- Thinner grooves

Cons:

- brittle edges prone to chipping

Tooled joints:

Tooled joints are etched into the concrete while it is hardening. These joints are also ¼ thickness of the concrete.

Pros:

- rounded edges that won’t chip

Cons:

- wider grooves

Besides these pros and cons, another factor is the aesthetic of cut vs tooled which is subjective but is a factor in deciding which way to go.